The future application of laser technology in both scientific and industrial applications will be the focus of activity at a prestigious conference in September.

The future application of laser technology in both scientific and industrial applications will be the focus of activity at a prestigious conference in September.

LANE 2014 is the 8th International Conference on Photonic Technologies. It takes place in Furth, Germany between 8-11th September. It aims to “offer a platform for an international exchange of ideas, opinions, perspectives, results and solutions concerning photonic technologies.” In fact over 180 talks will consider the scientific and industrial aspects of conventional laser processes like welding and laser cutting. The conference will also present the latest research and development results on emerging technologies such as ultrashort pulse processing, additive manufacturing, laser-assisted processes and simulation and modelling.

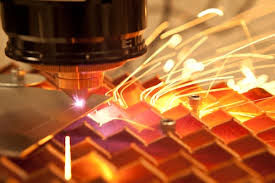

For example, ultra-short laser pulses provide a fast and precise way of processing a wide range of materials without excessive heat input and are providing opportunities to deliver the benefits of laser technology where it was previously thought not possible because controlling the properties of melted materials was extremely difficult.

This conference will present an opportunity to get up-to-date on the latest research and development, recent applications and future trends in the given topics. Amongst the most anticipated sessions are “Trends and developments in macro material processing” and “Optical systems for high-power laser applications”. There are five rooms dedicated to:

- Additive Manufacturing – LDMD and Cladding

- Additive Manufacturing – Simulation and Modelling

- Welding Metals – Hybrid

- Laser Cutting

- Surface Treatment

and each room has up to 10 plenary sessions each day as the Conference prides itself on an active programme that could uncover major developments in the use of laser technology across a wide range of sectors.

The future industrial applications of laser technology has recently been addressed by Hongqiang Chen, who leads new developments for GE in laser technology “As manufacturing becomes more advanced, we’re beginning to see laser technologies in manufacturing move from specialty applications to common tools used by manufacturing workers on the plant floor.”

Chen noted that the integration of laser tools and processes into manufacturing is all about going faster, greater efficiency, and improved performance. The global environment for manufacturing is becoming more and more competitive. With product cycle times getting shorter and labour costs rising in developing world, the premium today is on technology to be competitive. In manufacturing, companies are looking for ways to increase the speed and efficiency of production on their plant floors. Laser devices are key tools being used to help them achieve these goals. This should provide food for thought for LANE 2014.